Just How to Identify Common Repair Service Issues in Stretch Wrap Machines and When to Seek Professional Aid

Stretch Wrap equipments are important for efficient packaging procedures. They can experience various concerns that hinder performance. Operators has to be cautious in acknowledging indications of breakdown, such as inconsistent movie tension or uncommon noises. Understanding these usual repair service problems is important. Recognizing when to look for specialist assistance can make a considerable distinction. The nuances of troubleshooting and upkeep are worth exploring additionally.

Recognizing the Essentials of Stretch Wrap Machines

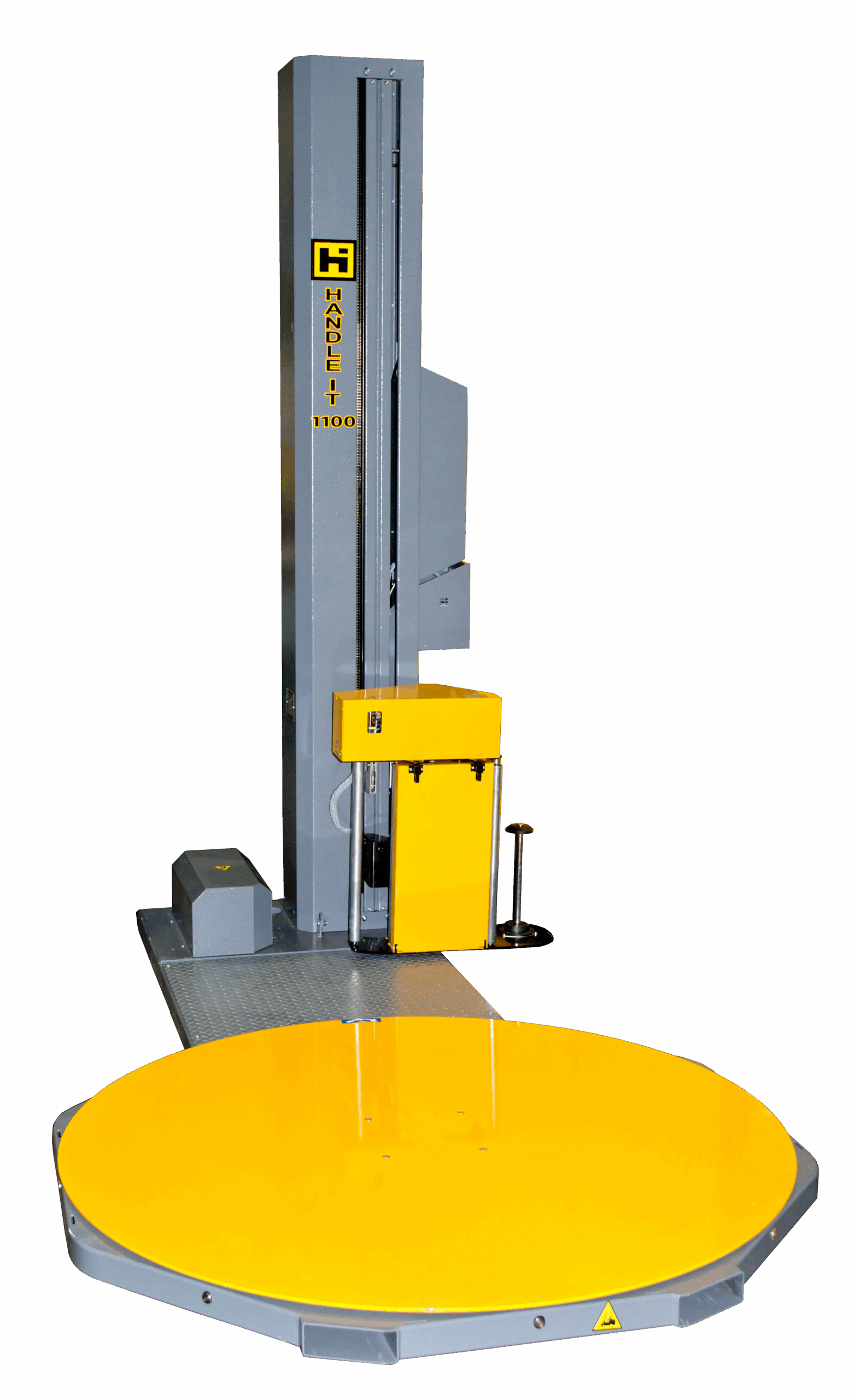

Stretch Wrap equipments are crucial tools in the product packaging sector, designed to safely envelop products for storage and transport. These devices utilize stretch movie, which abides by itself, creating a tight and safety layer around things. Typically, they can be found in various types, consisting of manual, semi-automatic, and completely automatic designs, satisfying diverse manufacturing requirements. The procedure of a stretch Wrap device includes feeding the movie around the item, using stress, and sealing the Wrap, making certain that goods continue to be stable during transit.Key parts of these machines consist of the movie control, carriage, and turntable panel, each playing an essential function in the covering procedure. Efficiency is additionally improved by adjustable settings that enable individuals to personalize the tension and number of wraps. Recognizing these fundamentals aids operators maximize the machine's efficiency, guaranteeing suitable packaging quality and reducing the danger of item damages throughout handling or delivery.

Typical Problems With Stretch Wrap Machines

Product packaging effectiveness can be significantly jeopardized by typical concerns that occur with stretch Wrap devices. One widespread trouble is irregular film tension, which can result in poor lots stablizing and enhanced product damage throughout transportation. Additionally, movie damage frequently takes place, interrupting the wrapping process and causing delays in operations. Another problem is the incorrect alignment of rolls, which can cause irregular covering and wastage of materials.Malfunctions in the control panel may additionally hinder functionality, making it challenging to keep track of or readjust settings efficiency. Electric problems, such as defective circuitry, can even more add to operational inadequacies. Routine upkeep can help alleviate much of these problems, ensuring the machine operates smoothly. Nevertheless, recognizing these usual issues is crucial for operators, as prompt intervention can avoid extra costly repair services and significant malfunctions.

Indicators Your Stretch Wrap Machine Demands Repair Service

When a stretch Wrap device shows uncommon noises throughout operation, it may suggest underlying mechanical problems. Additionally, irregular film stress and frequent downtime can even more signal that the equipment requires immediate interest. Recognizing these indicators early can aid avoid pricey fixings and ensure peak performance.

Unusual Sounds Throughout Operation

Unusual sounds during operation often signal underlying issues with stretch Wrap devices that need immediate attention. These audios may consist of grinding, squealing, or clanking, which can suggest damage on components such as gears, electric motors, or bearings. If the machine generates unforeseen sounds, it may be battling with imbalance or inadequate lubrication. Neglecting these audio hints can cause further damage and pricey repairs. Operators must conduct regular evaluations to recognize and attend to the resource of the noise without delay. Consulting the maker's manual can give certain standards for upkeep and troubleshooting. If the issue lingers after standard checks, looking for expert assistance is recommended to guarantee the device's durability and optimal performance.

Inconsistent Movie Stress

Inconsistent film stress can significantly impact the performance of stretch Wrap equipments, resulting in below average tons security and potential item damage. This issue often materializes as irregular wraps, where particular areas of the load are snugly secured while others are loosened. Operators may see that the stretch movie is either under-stretched or over-stretched, influencing its ability to adapt the lots. Furthermore, there may be visible indications of shifting or slippage during transport, showing that the movie is not providing sufficient assistance. Such inconsistencies can result from damaged parts, incorrect calibration, or malfunctioning sensors. Resolving these problems immediately is vital to guarantee peak maker efficiency and to avoid more difficulties that can occur from inadequate covering.

Frequent Downtime Issues

Frequent downtime problems can signify that a stretch Wrap device requires immediate repair service. These disturbances commonly indicate underlying mechanical failures or system breakdowns. Operators might notice raised regularity of jams, which disrupt the covering procedure and prevent efficiency. Uncommon noises during procedure can also function as warnings, recommending that components may be misaligned or worn. Additionally, inconsistent movie application can result in inadequate load defense, prompting further operational hold-ups. Overlooking these symptoms might lead to much more serious damages and pricey repairs. As a result, it is necessary for operators to monitor their machines very closely and resolve any type of indicators of malfunction quickly, making certain effective procedure and decreasing downtime in the long run. Seeking expert support might be needed for intricate problems.

Repairing Minor Issues

Repairing small troubles in stretch Wrap makers needs a methodical method to recognize and settle concerns effectively. Operators ought to begin by examining the power supply and making certain all links are safe. If the equipment does not start, verifying the breaker and merges can often disclose basic electric issues. stretch wrap machine repair near me.Next, examining the stretch here are the findings Wrap film for proper placement is crucial. Misalignment can lead to unequal wrapping and could call for adjustment of the movie rolls. Furthermore, operators should check the tension setups; inaccurate tension may lead to poor Wrap quality.Routine maintenance, such as cleaning the rollers and ensuring they are devoid of particles, can likewise stop minor troubles from escalating. Ultimately, keeping an eye on the device's efficiency can assist in determining patterns that show underlying concerns. By dealing with these tiny worries without delay, drivers can keep peak functionality and stay clear of bigger malfunctions

When to Hire a Professional

Operators may find themselves confronted with concerns that expand past minor changes and routine maintenance. In such cases, identifying the best minute to contact an expert becomes crucial. It may suggest a much deeper electrical or mechanical mistake if the stretch Wrap maker constantly falls short to operate correctly regardless of repairing initiatives. In addition, uncommon sounds, persistent error messages, or failure to Wrap tons safely are indications that know-how is needed.Furthermore, if the machine experiences regular malfunctions or if parts are harmed, a professional's treatment is essential to avoid more complications. Operators needs to additionally consider employing aid when unfamiliar with particular repair service techniques or when security risks exist. Ultimately, timely professional aid can not just resolve complicated concerns yet likewise prevent costly downtime and warranty top performance of the stretch Wrap equipment.

Preventative Upkeep Tips for Stretch Wrap Machines

Often Asked Inquiries

What Is the Typical Life Expectancy of a Stretch Wrap Maker?

Can I Utilize Different Kinds of Stretch Movie on My Machine?

Various kinds of stretch movie can be made use of on an equipment, but compatibility and performance may differ - stretch wrap machine repair near me. It's essential to speak with the equipment specs and supplier standards to assure the most effective outcomes and avoid possible issues

How Can I Enhance the Efficiency of My Stretch Wrap Machine?

To boost stretch Wrap maker effectiveness, regular upkeep, perfect movie tension setups, proper positioning, and employee training are essential. Additionally, updating components and lessening downtime through effective workflow can significantly improve overall efficiency and outcome.

Exist Any Type Of Details Brands Known for Dependability?

Several brand names are identified for their reliability in stretch Wrap devices, including Signode, Lantech, and Aetna. Customers often commend these suppliers for their toughness, efficiency consistency, and solid consumer assistance, boosting overall operational performance.

What Is the Cost Range for Expert Repairs on Stretch Wrap Machines?

The expense variety for expert fixings on stretch Wrap devices varies significantly, generally in between $150 to $1,500, depending on the complexity of the problem, parts called for, and the technician's know-how associated with the repair procedure. The operation of a stretch Wrap machine entails feeding the film around the item, applying tension, and sealing the Wrap, making sure that items remain secure throughout transit.Key parts of these makers consist of the film control, turntable, and carriage panel, each playing an important duty in the wrapping process. Irregular film stress can significantly influence the performance of stretch Wrap makers, look at here leading to substandard load security and possible product damages. Frequent downtime concerns can signify that a stretch Wrap device calls for urgent repair service. The typical life expectancy of a stretch Wrap maker commonly varies from 5 to 15 years, depending on usage, upkeep, and the high quality of the device. To enhance stretch Wrap maker efficiency, regular upkeep, perfect film stress settings, appropriate placement, and employee training are vital.